- Home Page

- Company Profile

-

Our Products

- Reactive Dyes

- REACTIVE VS DYES

- REACTIVE P And H DYES

- REACTIVE ME DYES

- REACTIVE RR DYES

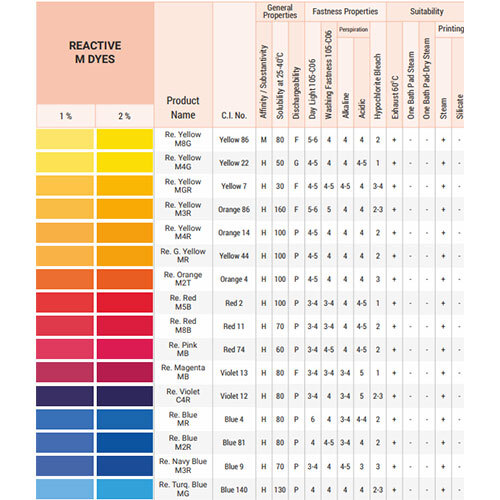

- REACTIVE M DYES

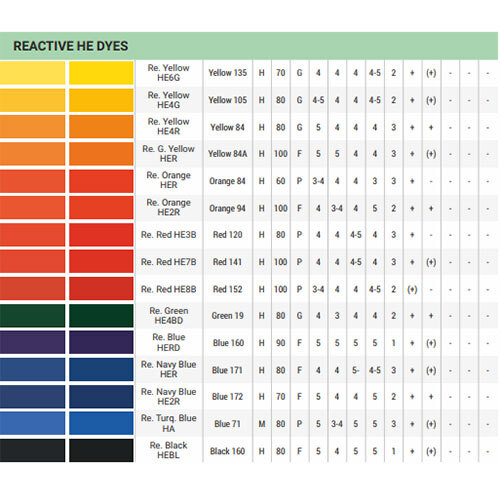

- REACTIVE HE DYES

- Reactive Cold Brand Dyes

- Reactive 'HE' DYES

- Reactive Bifunctional Dyes

- Reactive Vinyl Sulphone Dyes

- Reactive Orange Dyes

- Reactive Yellow H4g

- Reactive Red BS Dyes

- Reactive Hot Brand Dyes

- Reactive Yellow RGB Dyes

- Reactive 'H' DYES

- Reactive Violet Dyes

- Reactive Dyes

- Reactive Yellow Dyes

- Reactive Red Dyes

- Reactive Black Dyes

- Reactive Blue Dyes

- He Dyes

- Direct Dyes

- Acid Dyes

- Food Colors

- REACTIVE M DYES

- REACTIVE RR DYES

- REACTIVE VS DYES

- Re. Yellow GR

- Re. Yellow H7GL

- Re. Yellow G

- Re. Yellow FG

- Re. Yellow GL

- Re. G. Yellow RNL

- Re. G. Yellow R

- Re. Orange 2R

- Re. Orange 3R

- Re. Brill. Red BB

- Re. Red 5B

- Re. Red C2G

- Re. Red RB

- Re. Brown GR

- Re. Violet 5R 140

- Re. Blue 3R

- Re. Navy Blue GG

- Re. Brill. Blue BB

- Re. Navy Blue RGB

- Re. Navy Blue G133

- Re. Black B 150

- Re. Blue R

- Re. Black WNN

- Re. Black HFGR

- REACTIVE P&H DYES

- REACTIVE ME DYES

- REACTIVE HE DYES

- Reactive Dyes

- Contact Us

Reactive Hot Brand Dyes

1.60 - 4.90 USD ($)/Kilograms

Product Details:

- Application Cellulose fibers such as cotton, viscose, and blended fabrics

- Ph Level 6-7 (1% solution)

- Purity 96-98%

- Solvent Color Characteristic (Varies per shade)

- Grade Industrial

- Size Available in 25 kg / 50 kg bags

- Water Resistance Excellent

- Click to View more

X

Reactive Hot Brand Dyes Price And Quantity

- 1.60 - 4.90 USD ($)/Kilograms

- 500 Kilograms

Reactive Hot Brand Dyes Product Specifications

- Hot Brand Reactive Dyes

- 235-424-6

- 24 months in original packaging

- Available on request

- NO

- 0.7 Gram per cubic centimeter(g/cm3)

- Fine Powder

- Decomposes before melting

- Good to excellent

- Odorless

- C29H19ClN7Na3O11S3 (Example: Reactive Red 195)

- Easily soluble in water

- Cellulose fibers such as cotton, viscose, and blended fabrics

- 6-7 (1% solution)

- Reactive Dye

- 96-98%

- Characteristic (Varies per shade)

- Excellent

- Textile Dyestuffs

- Available in 25 kg / 50 kg bags

- Industrial

- 100% / 200% (Standardized)

- Powder

- 32041600

- 1.0%

- Good to washing, light, perspiration, and rubbing

- 12225-84-2

Reactive Hot Brand Dyes Trade Information

- 100000-150000 Kilograms Per Month

- 7 Week

Product Description

We are a renowned organization which is popularly engaged in supplying reactive hot brand dyes. The reactive dyes have great importance for printing of cotton material. These are used for dyeing purpose. The colorants are strong and available in many shades. The dyes are also successfully applied on polyamide and wool materials. The reactive hot brand dyes are demanded in the textile industry and thus our customers always remain satisfied with the remarks for the dyes quality.Superior Dye Fixation for Bright Results

With high fixation rates achieved through appropriate alkali use, these hot brand reactive dyes ensure vivid, uniform coloring on cotton, viscose, and blended fabrics. Their chemical structure promotes strong dye-fiber bonds, resulting in excellent colorfastness to washing, light, and perspiration. This guarantees lasting brilliance and durability for all your textile applications.

Versatile Application and Compatibility

These dyes cater to a wide range of textile processessuitable for batch or continuous dyeing methods in both industrial and export markets. The granular or powdered forms dissolve rapidly, while their compatibility with most textile auxiliaries streamlines integration into diverse manufacturing routines, making them reliable for large-scale and customized dyeing needs.

Eco-Friendly and Safe Formulation

Formulated to be azo-free and low in heavy metals, these reactive dyes align with environmental and health safety standards. Odorless, non-poisonous, and dust-free, their use reduces environmental impact without compromising on performance. Storage in cool, dry conditions further preserves dye quality and safety throughout their 24-month shelf life.

FAQs of Reactive Hot Brand Dyes:

Q: How are Reactive Hot Brand Dyes applied to textiles?

A: Reactive Hot Brand Dyes are typically applied using either batch or continuous dyeing methods at a high temperature range of 8090C. An appropriate amount of salt and alkali is used to achieve optimal dye fixation, ensuring strong bonding with cellulose fibers such as cotton or viscose.Q: What benefits do these dyes offer for textile applications?

A: These dyes deliver exceptional color brilliance, high wash, light, and rubbing resistance, and uniform coverage. Their strong fixation rate ensures durable and vibrant colors, while their compatibility with most auxiliaries makes them versatile for various textile dyeing processes.Q: When should these dyes be used for optimal results?

A: They should be used when high fixation, excellent fastness properties, and eco-friendly requirements are prioritiesespecially for fabrics made of cotton, viscose, or blends. Using them at the recommended temperature and with proper alkali maximizes their performance.Q: Where should Reactive Hot Brand Dyes be stored?

A: Store these dyes in a cool, dry place away from direct sunlight to maintain product integrity. Their HDPE/PP packaging with inner liners provides additional protection during storage and transportation.Q: What is the process for achieving high fixation with these dyes?

A: Achieving high fixation involves using the recommended dyeing temperature (8090C), maintaining a medium to high salt concentration, and introducing the correct type and amount of alkali. This process activates the reactive groups, enabling stable dye-fiber bonds.Q: What makes these dyes eco-friendly?

A: They are formulated to be azo-free and contain low levels of heavy metals, reducing their impact on the environment and enhancing safety for operators and end users. They are also non-poisonous and essentially odorless.Q: How does solubility and formulation impact dyeing performance?

A: The dyes easily soluble, dust-free granule or powder forms allow for rapid dispersion in water, ensuring consistent and even dyeing. Their purity (9698%) and standardized strength further support predictability and high-quality results.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free